Electricity costs in the Philippines continue to climb, and the national grid faces growing pressure from population growth and extreme weather. Businesses are beginning to rethink how they manage power. Many are moving toward customized energy solutions that combine solar, battery storage, and intelligent load management.

These systems are not one-size-fits-all. Each is engineered to match a company’s exact energy profile, operations schedule, and financial objectives. The result is lower costs, greater reliability, and energy independence that shields a business from the volatility of the grid.

Why tailored systems are essential in 2025

Every business uses energy differently. A hotel needs cooling systems that run continuously. A call center depends on server uptime. A warehouse must maintain temperature control at night, while a manufacturing plant needs voltage-stable power during production peaks.

Off-the-shelf solar packages rarely address these differences. A tailored energy system starts with understanding how each facility actually consumes power. It looks at load curves, peak times, and backup requirements before a single panel is selected. This level of detail allows the system to deliver both higher returns and stronger resilience.

What goes into a customized energy setup

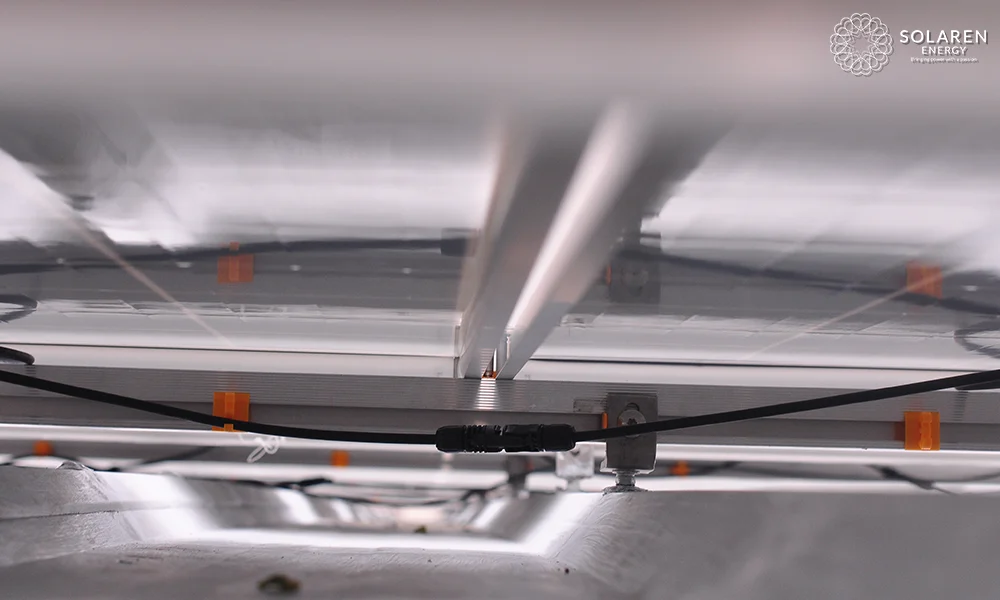

A modern customized system begins with energy profiling. Engineers audit twelve months of electricity bills and monitor real-time usage to map how power is consumed throughout the day and across seasons.

Once the data is clear, designers match solar generation with battery storage to ensure that critical equipment continues running even when the grid is unstable. Smart software manages when to store energy, when to draw from batteries, and when to sell excess power back to the grid.

Everything is built within the Philippine interconnection and net metering standards, ensuring compliance and smooth integration with local utilities.

The business impact

Well-designed customized systems can cut electricity bills by thirty to sixty percent. They reduce equipment downtime, improve power quality, and meet ESG and supply chain requirements for renewable sourcing.

For sectors like food processing, logistics, and manufacturing, this reliability can decide whether deadlines are met or revenue is lost. Battery-supported systems also keep operations steady during brownouts, which remain common across several regions.

At Solaren, we simulate system performance before deployment, projecting ROI, outage coverage, and tariff savings so business owners understand the outcome before investing.

How different industries apply it

Hotels and resorts shift air-conditioning and pool loads to daytime solar production, cutting diesel generator use.

Cold storage operators run compressors on battery power at night to prevent spoilage.

Factories stabilize voltage to protect sensitive machines and maintain continuous automation.

Retail chains use programmable inverters to keep lighting and point-of-sale systems online during power interruptions.

Each setup is unique, but all share one goal: uninterrupted operations with lower energy costs.

Incentives that make adoption easier

Government support continues to improve the economics of renewable investment. Through the Green Energy Option Program (GEOP), qualified users can source power from renewable providers, often at lower rates than traditional utilities.

The Energy Regulatory Commission now recognizes behind-the-meter batteries as part of renewable energy storage solutions, allowing businesses to earn credits of ₱5.638 per kilowatt-hour for solar energy exported after sunset.

Projects commissioned before December 2026 enjoy further benefits such as VAT-free import of battery components and access to green installation grants. Solaren manages all applications and permits under its turnkey energy program to ensure compliance from start to finish.

Technology choices that shape performance

The technology behind modern solar installation in the Philippines continues to evolve. Lithium Iron Phosphate (LFP) batteries remain the safest and most reliable option for daily cycling. Sodium-ion batteries, now emerging, charge faster and offer lower costs per cycle. Vanadium flow batteries are gaining attention for large industrial systems, offering more than twenty years of life without fire risk.

Hybrid inverters connect all these elements, allowing solar, storage, and grid power to work together intelligently. This single-device management simplifies operation and improves system efficiency.

Real-world example: Cavite logistics facility

A regional logistics hub in Cavite installed a 350-kilowatt rooftop solar system paired with a 240-kilowatt-hour LFP battery bank. The software prioritized cooling, security, and loading dock operations. The result was a fifty percent drop in peak-hour consumption and zero downtime during two scheduled outages. The investment is projected to break even in under four years and will continue to generate savings for more than a decade.

Financing that supports growth

Many businesses still assume solar and storage require a heavy upfront payment. In reality, green loans and lease-to-own programs through local banks and partner financiers make adoption straightforward. Terms typically run three to five years at rates between six and eight percent, and in many cases, monthly repayments are already lower than previous electricity bills. The project starts saving money from the first month of operation.

The long-term advantage

Battery prices are expected to decline while grid instability and carbon charges are likely to rise. Companies that invest early lock in lower energy costs and protect their infrastructure from disruptions.

Customized energy systems provide more than savings. They create independence, resilience, and sustainability in a country where energy uncertainty is still part of doing business. For Philippine enterprises preparing for the future, a tailored solution is not a luxury. It is a necessity that ensures stability, efficiency, and competitiveness for decades to come.