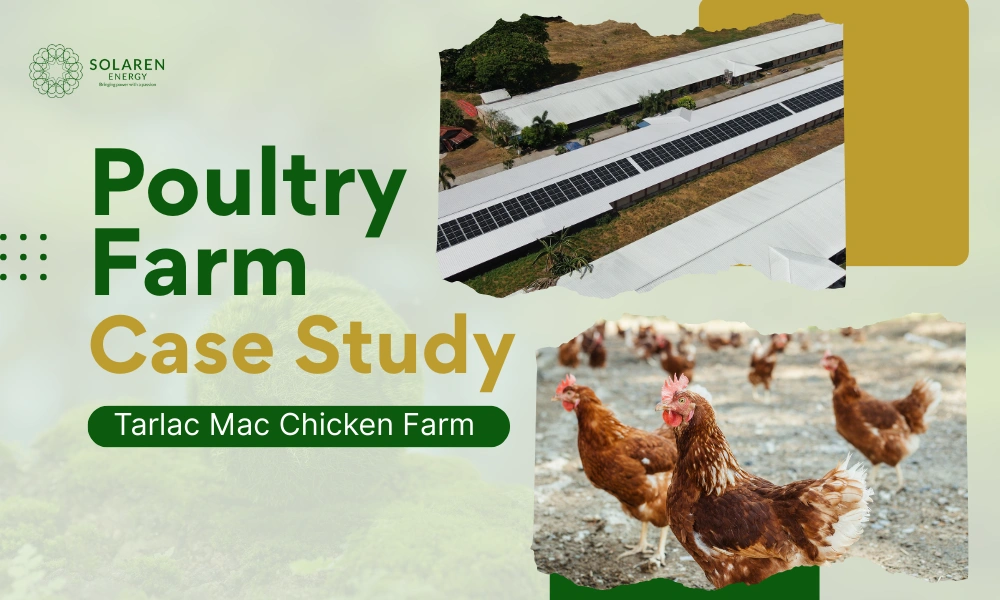

Solaren Renewable Energy Solutions installed this 100 kWp solar system for a poultry farm in Tarlac to cut daytime energy costs and improve operational reliability. This case study uses verified utility bills and SMA EnnexOS meter data to show real savings achieved under the DOE net-metering program.

Real bills. Real meter data. This 100 kWp solar case study shows what happened on a poultry farm in Tarlac using bifacial TOPCon modules and an SMA CORE2 110 kWac inverter. We reconciled audited utility bills with SMA EnnexOS readings (CT accuracy ±1%). No glossy estimates, no sales talk or claims. Pure math.

Quick facts you can scan

- Tracking window: May 11, 2022 – Sept 11, 2025 (40 billing months)

- Generation: 458,456 kWh

- Used on-site: ~80.3% (368,382 kWh)

- Exported with credit: ~19.7% (90,074 kWh at ~₱6.81/kWh)

- Verified savings from bills: ₱5,759,547 total (≈ ₱147,681/month)

- Specific yield: ~1,375 kWh/kWp-year

- Equipment failure downtime: 0

- First 5 months: ran without export credit while net metering was pending

What makes this “proof,” not pitch

- Every month, matches a paid bill and the plant’s meter exports.

- The data shows how the farm lived with solar through seasons and grow-out cycles.

- Most posts talk in generalities. This poultry farm solar Philippines example shows receipts.

The site and the design choices

- Array: 100 kWp DC, bifacial TOPCon on a white reflective roof

- Inverter: SMA CORE2 110 kWac (headroom, no clipping risk)

- Layout: South-facing, ~10% tilt, zero shade

- Tap point: Very close to the main panel, so wiring losses stay low

- Care: Routine cleaning; you can see steadier shoulders after wash days

How the energy landed

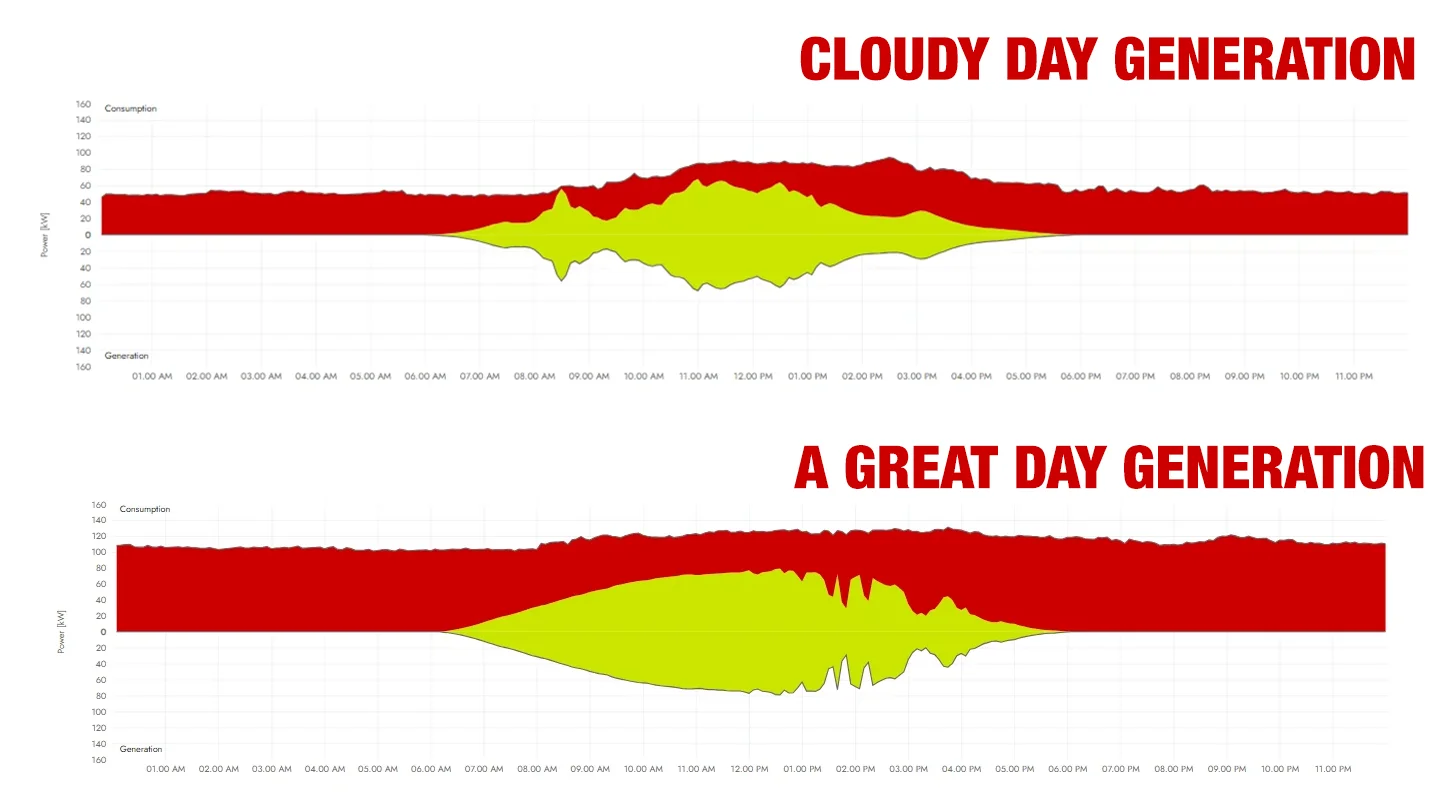

- The farm’s daytime load means self-consumption does the heavy lifting.

- When barns work harder, export falls toward 0–3%. During the lighter months, export rises.

- That’s what you want: right-sized PV feeding the right hours.

Bills, reconciled

- Modeled bill without solar for the same dates: ₱19,289,896

- Actual bill with solar: ₱13,405,694

- Difference (savings): ₱5,759,547 over 40 months

- Feed-in credits contributed ₱613,592 in total. Useful, but not the main driver.

Why net metering mattered

About one-fifth of the generation was exported. With net metering in place, that energy earned a credit. Without an approved interconnection, that same energy would have been curtailed and wasted. Compliance preserved value and shortened payback.

[PLACE CHART: Cumulative savings from day one]

Seasonality and “real life”

- Peak stretch: March–April 2025 (16.9–18.4 MWh per month)

- Softer months: December–January (≈ 7–10 MWh)

- Operations never stopped: zero equipment-failure downtime across the record.

What a Customer should copy from this project

- Get the interconnection moving early. The first five months here had no export credits; the system still saved money, but approvals added back value.

- Keep cable runs short and use a tap point close to the main panel.

- Protect shoulder hours. Bifacial on a white roof + regular cleaning helped mornings and late afternoons.

- Ask for evidence. For any farm quote, request 12 months of bills from a comparable site and portal screenshots that match those months.

FAQ

- How much did export pay?

Ans: On average ~₱6.81/kWh across the period. - What about payback?

Ans: We don’t publish capex. On current pricing, “sub-three years” is accurate for similar farms. A practical public range: 2.5–3.5 years. - Can homes copy this?

Ans: Homes peak at night. Farms and other daytime operations usually capture more value.

What this case study proves

- Solar matched the load: roughly four out of five kilowatt-hours stayed on site.

- Net metering turned the remaining fifth into credit rather than waste.

- Clean design and basic care (wash, inspect, keep runs short) did visible work.

- You can run a 100 kWp solar case study on real data, not promises.