A real operating account from the Philippines

Since October last year, Solaren has been quietly changing how we move people and equipment day to day. There was no pilot programme and no press announcement. We started replacing conventional vehicles with a mix of electric and hybrid models and watched what happened over time. The EV and Hybrid Fleet Fuel Savings are listed below.

The fleet now includes several BYD hybrids, a fully electric BYD Dolphin, a Tesla Model Y, and a Toyota Corolla Cross Hybrid. These vehicles are used for ordinary work. Site visits. Project meetings. Long provincial drives. Daily errands. They are not demonstration units, and they are not driven gently to prove a point. They are used in the way company vehicles usually are.

What follows is not a projection or a model. It is an account of what actually changed once those vehicles were on the road.

Fuel use before the transition

Before the transition, fuel use across the fleet was predictable in the wrong way. Average consumption was around nine litres per hundred kilometres. Fuel prices hovered around sixty pesos per litre and moved often enough to make monthly costs hard to forecast. It was an expense that could not be optimized. It could only be endured.

Hybrid vehicle performance in daily use

Once the new vehicles were introduced, the difference became apparent slowly, then unmistakably. The BYD Sealion hybrids, driven on mixed city and provincial routes, covered several thousand kilometres each while using a fraction of the fuel required previously.

One vehicle travelled just over 5,000 kilometres and consumed roughly a fifth as much fuel as an equivalent petrol car would have. Another covered a similar distance and used even less. There was nothing clever about the driving and no effort to game the numbers. The savings came from how the vehicles were designed to operate.

Fully electric vehicles and fuel elimination

The fully electric vehicles changed the picture more dramatically. The BYD Dolphin has now covered close to fifty thousand kilometres. Had that distance been driven in a conventional car, it would have required well over four thousand litres of fuel. Instead, fuel use dropped to zero.

The Tesla Model Y, although newer to the fleet, follows the same pattern. Every kilometre driven would previously have depended on petrol.

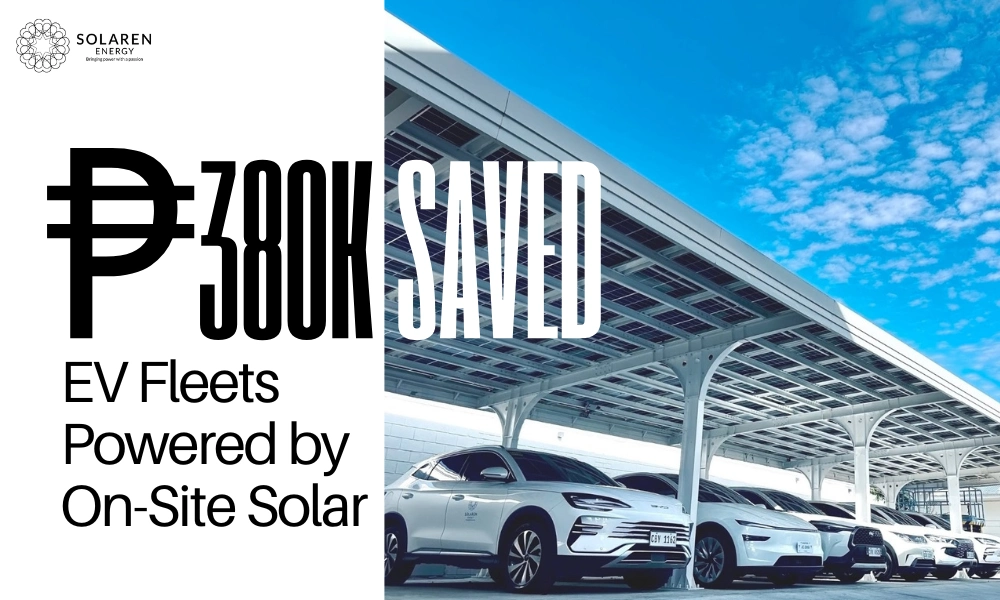

Solar charging and on-site energy use

What makes this more than a vehicle story is how the cars are charged. A thirty-four-kilowatt peak solar carport supplies power during the day. Vehicles are plugged in when they are parked at the office, usually during daylight hours. As a renewable energy company, we are lucky to have this 34kWp system, both net metered and powered by powerful hybrid inverters and additional batteries.

Many of the kilometres driven are therefore powered directly by solar generation rather than the grid. In practical terms, that means cars leaving the office fully charged without drawing energy from the utility. Where vehicles are charged using the utility, net metering offsets the cost.

Measured savings to date

Over several months, these small changes accumulated into something substantial. More than six thousand litres of fuel were no longer needed. The direct cost savings amounted to roughly 380,000 pesos.

That figure does not include significantly reduced servicing costs, fewer oil changes, or quieter wear patterns in brakes and drivetrains. It simply reflects fuel not purchased

Day-to-day operational changes

What stands out is not the technology. Electric and hybrid vehicles are no longer unusual. Once everything is running, the most significant change is the lack of drama.

Fuel stops being part of the weekly budgeting. Pump prices come and go without forcing a rethink. Planning gets easier, not because anything clever is happening, but because fewer things can swing the numbers around.

There is also a subtle operational shift. Drivers and vehicle users need to think ahead and plan to be ready when needed. Drivers spend less time detouring for fuel. There is less noise and heat during long days of travel. None of this shows up in a spreadsheet, but it is noticed by the people using the vehicles every day.

From experiment to infrastructure

Living with the setup starts to change how you think about electrification in the Philippines. Once the cars are charged on site using solar power, they stop feeling like a fashion statement and become just another part of basic infrastructure.

Fuel prices still move, but they matter less. Mobility begins to behave more like a known cost than a variable one.

There was no point where the switch to EVs felt instantly significant. It happened in the background. At some stage, fuel just stopped being something that came up in day-to-day planning. When the figures were eventually reviewed, they lined up with what had already been apparent from regular use. Based on that experience, we plan to add more service vehicles as practical EV options become available.

Solar Energy Fleet is not yet fully converted to Electric Vehicles, but it will be eventually. The future looks very different.

What this case demonstrates

This is not a pitch to rush out and replace an entire fleet, nor is it about chasing the latest idea. It is simply an account of what happens when electric vehicles and on-site solar are used as practical tools.

The savings show up in real use. The data comes from vehicles still doing their jobs. Nothing about the outcome is hypothetical.

It is simply what has happened so far.