Industrial solar power systems in the Philippines operate on a scale that demands more precision, more coordination, and more accountability than smaller projects. Roofs are larger, energy demands are higher, and the risks of downtime are far greater. When a factory or production site runs 24 hours a day, every design choice must consider not just efficiency but safety, durability, and long-term stability.

The goal is not just to install panels. It’s to build an energy system that performs reliably for decades.

Understanding your energy profile

The first step is to map how your facility actually consumes power. This starts with reviewing at least a year of electricity bills to see how demand changes across seasons. If possible, include hourly load data to capture the peaks and dips in energy use.

Industrial operations are rarely simple. They often have multiple shifts, heavy machinery, and time-specific loads like compressors, chillers, or production lines. Designing for these realities ensures that the system generates power when it’s needed most. A cookie-cutter design that works for an office or warehouse won’t work for a manufacturing plant.

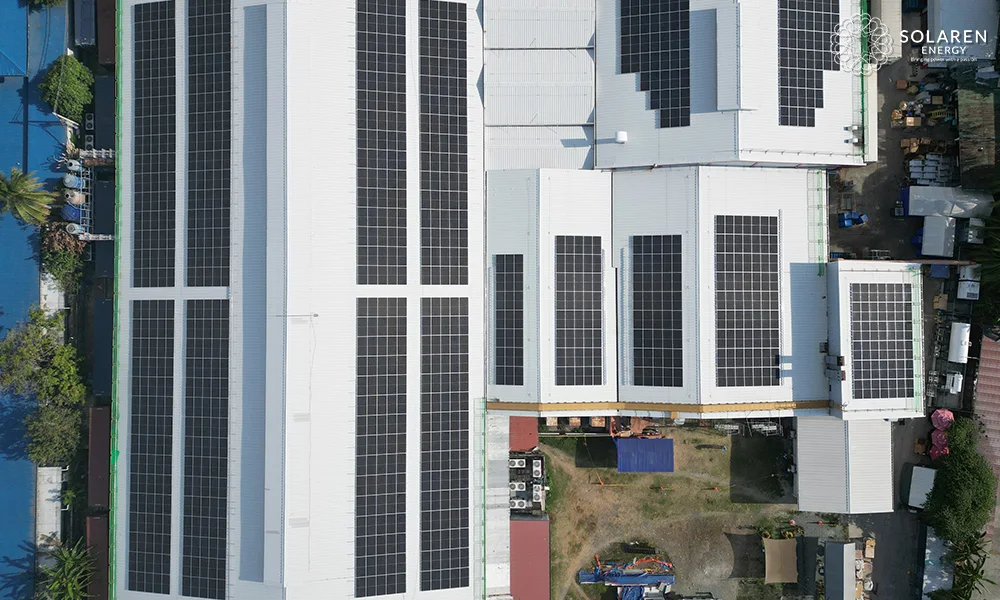

Structural and roof considerations

Industrial roofs can cover thousands of square meters, but not all of that area can safely carry solar panels. The combined weight of panels, racking, and ballast must be checked carefully against the roof’s load capacity. Fire lanes, skylights, and ventilation spaces need to remain unobstructed.

For facilities near coastal or high-wind areas, corrosion and wind uplift are major considerations. Every project should include a full structural assessment before any equipment is ordered. Solaren often engages independent engineers to validate loading plans, which avoids costly redesigns later on.

The roof is not just a surface for panels; it’s part of the structural system. Designing correctly from the start saves time, materials, and money.

System design for high demand

Industrial solar projects must balance production and self-consumption. The design should maximize on-site usage to reduce grid exports while keeping generation stable throughout the day.

Choosing the right inverters is crucial. Industrial systems require inverters that can handle high continuous power and maintain uptime even under extreme conditions. The DC-to-AC ratio should be optimized to deliver peak performance during midday hours without overloading the system.

In some cases, adding battery storage makes sense. Energy storage helps facilities manage peak demand charges and maintain operations during grid fluctuations. It turns solar from a simple cost saver into a genuine energy management tool.

Coordinating with the utility

Larger solar systems involve deeper coordination with the local electric utility. That process often includes detailed single-line diagrams, transformer capacity checks, and protection relay settings to prevent grid disturbances.

Utility approvals for industrial solar power systems in the Philippines take more time than smaller commercial installations. Engaging the utility early avoids bottlenecks that could delay commissioning. Solaren’s engineers maintain direct communication with utility teams throughout the process to ensure all documents, safety clearances, and connection protocols are completed smoothly.

Managing procurement and logistics

For large-scale solar installations, procurement becomes a project in itself. High-volume equipment orders need careful scheduling and clear delivery commitments. Shipping delays or customs issues can disrupt entire construction timelines.

Before ordering, confirm supplier contracts with guaranteed delivery dates. Prepare staging areas for materials, and make sure cranes or hoists are suited to the site layout and load weight. Solaren manages all logistics internally, coordinating between suppliers, customs brokers, and site managers to keep everything aligned.

Working in active facilities

Most industrial installations happen in facilities that cannot afford downtime. The challenge is to maintain normal operations while construction is ongoing.

The safest approach is to work in sections, isolating each area as it’s built. Electrical tie-ins should be scheduled during planned downtime, and safety perimeters must be enforced at all times. Clear communication with the client’s operations team is essential. Solaren routinely installs systems without interrupting production by working during low-load hours and holidays whenever possible.

Quality assurance and commissioning

Industrial solar projects are held to higher technical standards. Every connection and component must pass specific inspections. Torque checks for all mechanical fasteners, insulation resistance testing for cabling, and inverter configuration verification are all part of the commissioning checklist.

Once the system is operational, performance must be tested against design expectations. This includes verifying real output, checking for shading impacts, and calibrating monitoring systems. A system that passes commissioning cleanly is far less likely to face technical issues later.

Maintenance and monitoring

A well-designed industrial solar power system includes built-in access for maintenance. Walkways, safety anchors, and cable management routes allow technicians to clean and service panels safely.

Real-time monitoring is now standard for large systems. Dashboards alert operators to performance drops or faults immediately, allowing quick diagnosis before production is affected. Scheduled inspection, typically twice a year, keep everything in optimal condition.

Downtime in an industrial facility is costly. The value of rapid fault detection often outweighs the cost of the monitoring platform itself.

Financing and return on investment

Industrial solar systems are capital-intensive, but financing options have become more accessible. Some companies choose direct purchase for maximum long-term savings, while others prefer lease-to-own models that spread payments across several years.

Banks and green finance programs now offer credit lines based on projected energy savings. The savings come not only from reduced grid purchases but also from lower demand charges and better energy predictability. For many companies, solar becomes an asset that stabilizes energy costs for 20 years or more.

Long-term impact

When properly designed and maintained, industrial solar power systems Philippines deliver decades of value. They lower operating costs, improve energy security, and help companies meet sustainability goals. Just as importantly, they protect businesses from rising electricity rates and unstable fuel prices.

The benefits go beyond economics. Companies that invest in renewable energy strengthen their public image, attract environmentally conscious partners, and contribute directly to national energy resilience.

Solaren continues to design and build industrial solar systems across the country that combine engineering precision with proven reliability. Each project is built to perform under real-world conditions, from heat and humidity to grid fluctuations, so clients can depend on consistent energy, year after year.